OVERALL EQUIPMENT EFFECTIVENESS (OEE ) & PREDICTIVE MAINTENANCE

In the increasingly competitive world of manufacturing, manufacturers strive to implement solutions to enhance overall production.

A solution that has evidently shown improvements in productivity across the manufacturing industries is the implementation of the OEE concept.

WHAT IS EQUIPMENT EFFECTIVENESS (OEE) ?

OEE is the premier metric for measuring production efficiency across industries. OEE is calculated as the product of availability, performance & quality rates.

The OEE can be calculated by:

Availability equals to Total Run Time/Available Production Time

Performance equals to Standard Cycle Time X No Of Components Produced/Actual Run Time

Quality equals to No Of Non-Defective Component Produced/Total No Of Components Produced

Every manufacturer strives for 100% OEE. It may be possible in an ideal world, but in real-world conditions, there were numerous factors that can prevent manufacturers from achieving 100% OEE. With the main factor being machine availability, the manufacturers can ensure their overall machine availability by adapting predictive maintenance.

AN INTRODUCTION TO PREDICTIVE MAINTENANCE

Predictive maintenance is the maintenance technique that utilizes condition monitoring tools to keep track of the health of equipment to detect faults & predict equipment failure.

PDM MISSIONS & COST BENEFITS

- Optimum availability

- Optimum operating conditions

- Maximum utilization of maintenance resources

- Optimum equipment life

- Minimum spares inventory

- Ability to react quickly

Vibration Technology: Measuring vibration levels and frequencies of machinery and using that information to analyze the health of machines and their components.

Ultrasonic:

Uses sound to identify potentially failing assets by detecting high-frequency sounds and

converting them into audio and digital data.

Electrical:

Employed to examine the incoming power quality of assets using motor current readings from

clamp-on ammeters to measure the current in a circuit.

Visual Inspection: Visual inspection was the first method used for predictive maintenance. Almost from the beginning of the Industrial Revolution, maintenance technicians performed daily “walk-downs” of critical production and manufacturing systems in an attempt to identify potential failures or maintenance-related problems that could impact reliability, product quality, and production costs.

ESTABLISHING A PREDICTIVE MAINTENANCE PROGRAM

- Eliminate unnecessary maintenance.

- Reduce lost production caused by failures.

- Reduce repair parts inventory.

- Increase process efficiency.

- Improve product quality.

- Extend the operating life of plant systems.

- Increase production capacity.

- Reduce overall maintenance costs.

- Increase overall profits.

CONCLUSION: WORLD–CLASS MAINTENANCE

Overall equipment effectiveness (OEE) is the benchmark used for world-class maintenance programs. The OEE benchmark is established by measuring equipment performance. Measuring equipment effectiveness must go beyond just the availability or machine uptime. These factors of OEE availability of machine will be enhanced by using predictive maintenance tools. In PdM, machine failures can easily predict and resolve. Mostly in PdM, vibration analysis is the key factor to predict 60% of mechanical and electrical-related failures.

Plant efficiency improvements can be scarce and may only be achieved by streamlining maintenance processes.

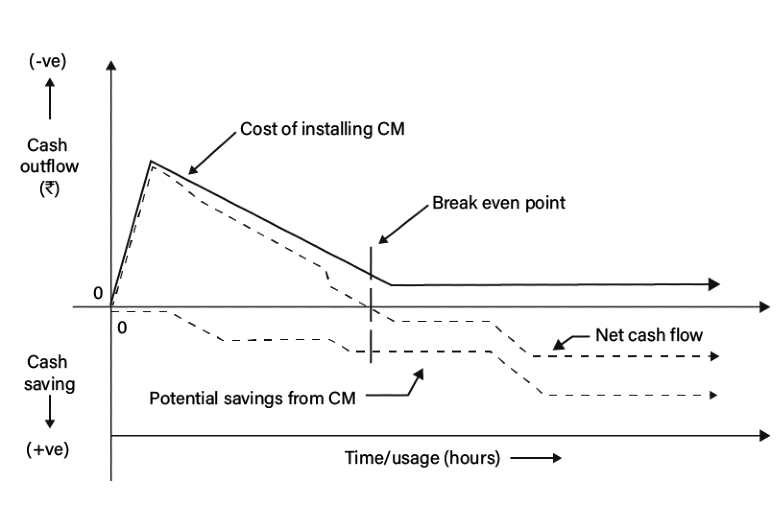

ARGUS: VIBRATION-BASED MACHINE CONDITION MONITORING SYSTEM