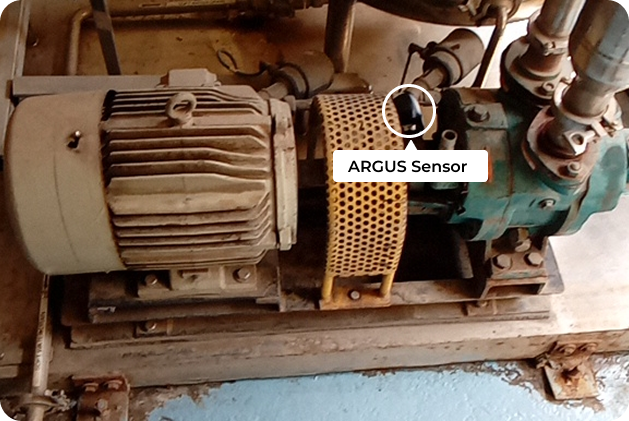

The Setup: Vacuum Pump for Clean Pharmaceutical Processing

The vacuum pump, used to maintain clean, low-pressure environments essential for safe, contamination-free, and thermally gentle processing in pharmaceutical operations, was reported to be generating abnormal noise. The customer asked us to check the vibration levels during an ARGUS Portable Vibration Analyzer demo.

ARGUS sensors were mounted at four standard locations:

- Motor Drive End (MDE)

- Motor Non-Drive End (MNDE)

- Pump Drive End (PDE)

- Pump Non-Drive End (PNDE)

Within minutes, ARGUS delivered the results — and they were anything but routine.

Figure 1 – Pump installation under evaluation

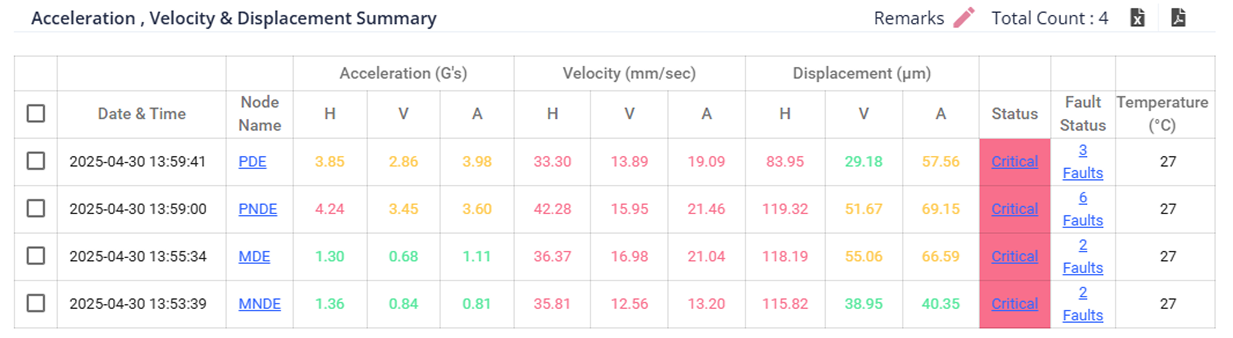

What the Data Showed: Critical Vibration Levels

Figure 2 – Acceleration, Velocity & Displacement across all four nodes

ARGUS flagged the pump as Critical based on ISO 10816 guidelines.

- Velocity RMS exceeded 7.1 mm/sec at every point

- Acceleration and displacement readings were within acceptable limits

- No bearing fault frequencies observed — this wasn’t a classic mechanical defect

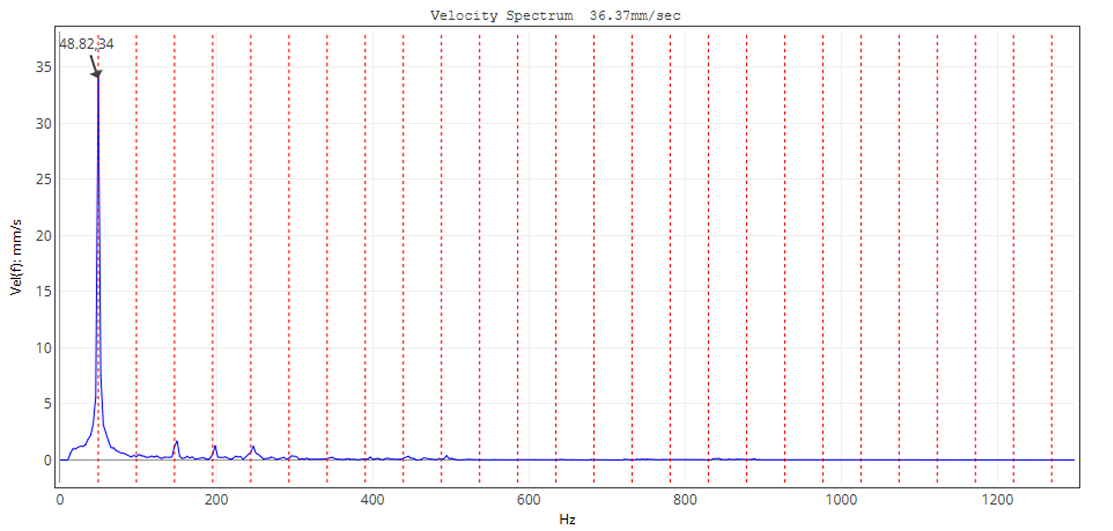

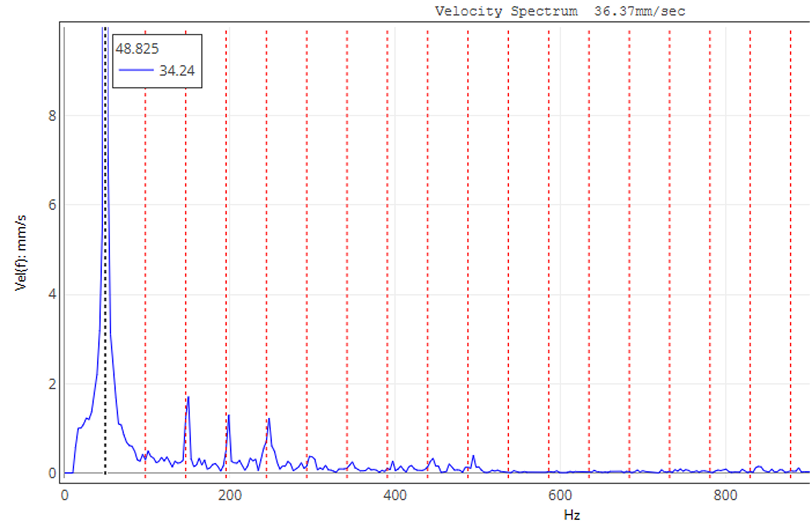

But the FFT spectrum from MDE-Horizontal told a different story:

- A strong 1× RPM component

- Pronounced 2×, 3×, 4×, and 5× harmonics — classic signs of structural issues

Figure 3a – Full FFT Spectrum from MDE-H

Figure 3b – Zoomed-in FFT showing 1× harmonics

What Was Causing It: Soft Foot & Base Looseness

A discussion with the customer confirmed:

- The baseplate had not been shimmed

- No prior checks for soft foot had been done

- Some base bolts were loose

Corrective action included:

- Ensuring proper base bolt torque as per OEM recommendations

- Anchoring the frame securely to the base

- Shimming to eliminate soft foot

- Rechecking alignment after soft foot correction

ARGUS follow-up data confirmed that:

- 1× and harmonic peaks dropped significantly

- RMS velocity returned below warning levels

Reactions on the Shop Floor

“We didn’t expect it to be this serious. The motor had been running — just a bit noisy.” “If vibration is this high, we need to check our other pumps too.” “We can fix this base — it’s actually a good thing you noticed it now.”

What Could’ve Happened If It Was Missed

If left unresolved, this fault could have led to:

- Seal or bearing failure

- Unplanned shutdown during production, causing batch losses

- Inefficient use of maintenance resources

- Regulatory risk due to utility disturbance in a GMP environment

Estimated loss avoided: ₹50,000–₹80,000 (from emergency repair, consultant diagnostics, and production downtime)

What This Shows

Even without prior alerts, vibration-based diagnostics can detect issues before they escalate — especially when combined with on-site context and physical inspection.

This case was a textbook example of:

- Soft foot and base looseness appearing as harmonic distortion

- A simple visual cue (“a bit noisy”) hiding a critical signature

- How real-time tools like ARGUS help teams move from reactive to predictive maintenance