In high-precision manufacturing, especially in fuel injector machining, even a minor defect can cascade into serious downtime and quality issues. This is especially true for high-speed spindles operating at 95,000 RPM, where early fault detection isn’t just helpful — it’s essential.

A leading automotive components manufacturer partnered with SANDS to implement ARGUS Continuous Condition Monitoring, leveraging real-time vibration analysis and AI-powered diagnostics to move from reactive to predictive maintenance.

The Problem: Unpredictable Spindle Failures

The manufacturer faced recurring challenges with its high-speed spindles used to drill fine orifices (4–6 mm) in fuel injector nozzles:

- Sudden bearing failures led to unplanned line stoppages.

- Standard ISO 10816 vibration thresholds were inapplicable at such high spindle RPMs.

- Coolant splashes made traditional sensors unreliable.

- A fault in one spindle could halt the entire production line, impacting output and cost.

The Solution: Real-Time Spindle Monitoring with ARGUS

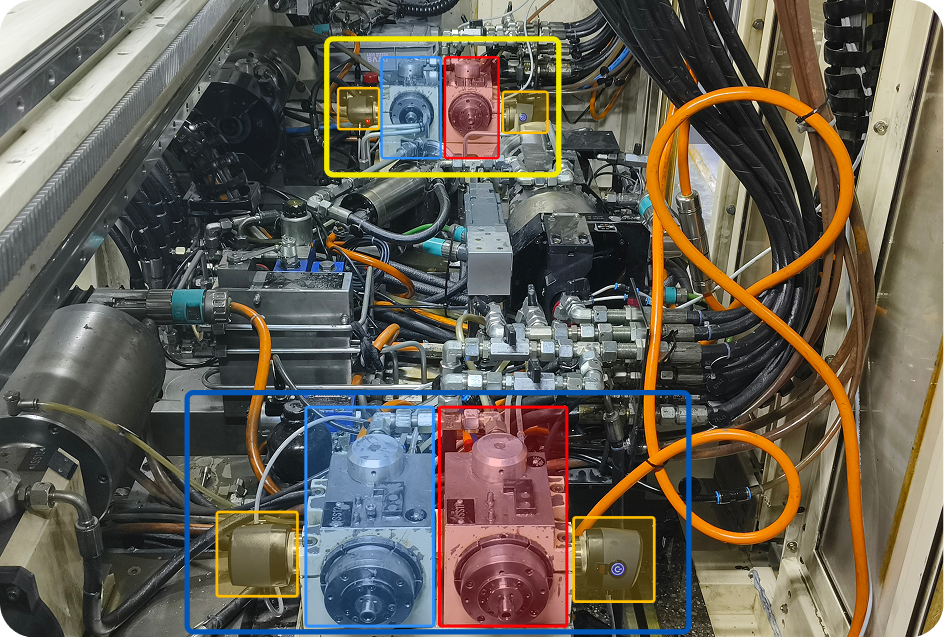

To address these challenges, four SANDS ARGUS vibration sensors were deployed across two tandem spindle sets — each consisting of one bore spindle and one seat spindle.

Key setup details:

- Direct-drive spindle configuration made the system highly sensitive to imbalance or misalignment.

- Customized thresholds were set based on empirical vibration data:

| State | Acceleration (g) |

|---|---|

| Normal | ≤ 2 g |

| Marginal | 2 – 4 g |

| Critical | > 4 g |

Timeline

Figure 1: Image of spindle setup and sensor locations

ARGUS vibration sensors were installed at the drive ends of all four spindles (2 bore + 2 seat). Baseline data showed normal sinusoidal signals on all units.

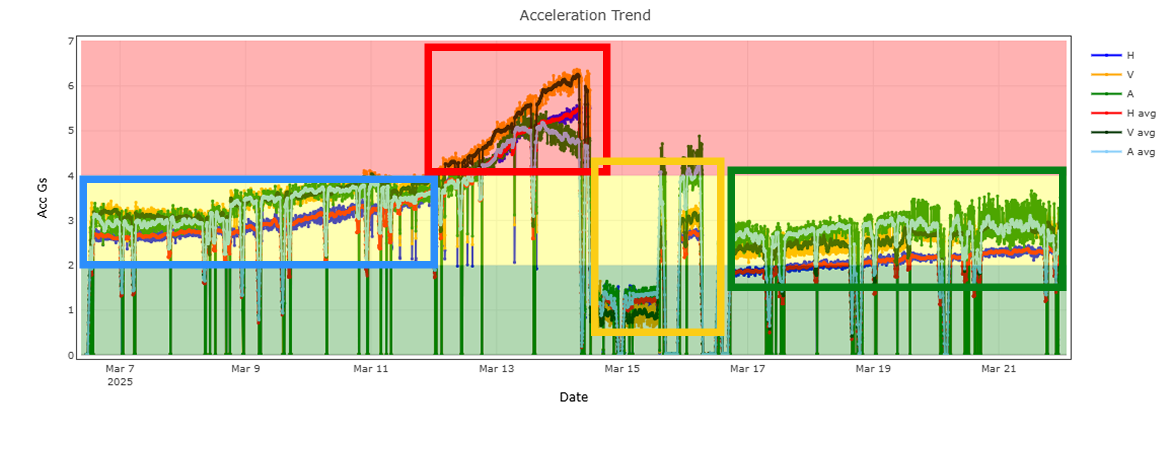

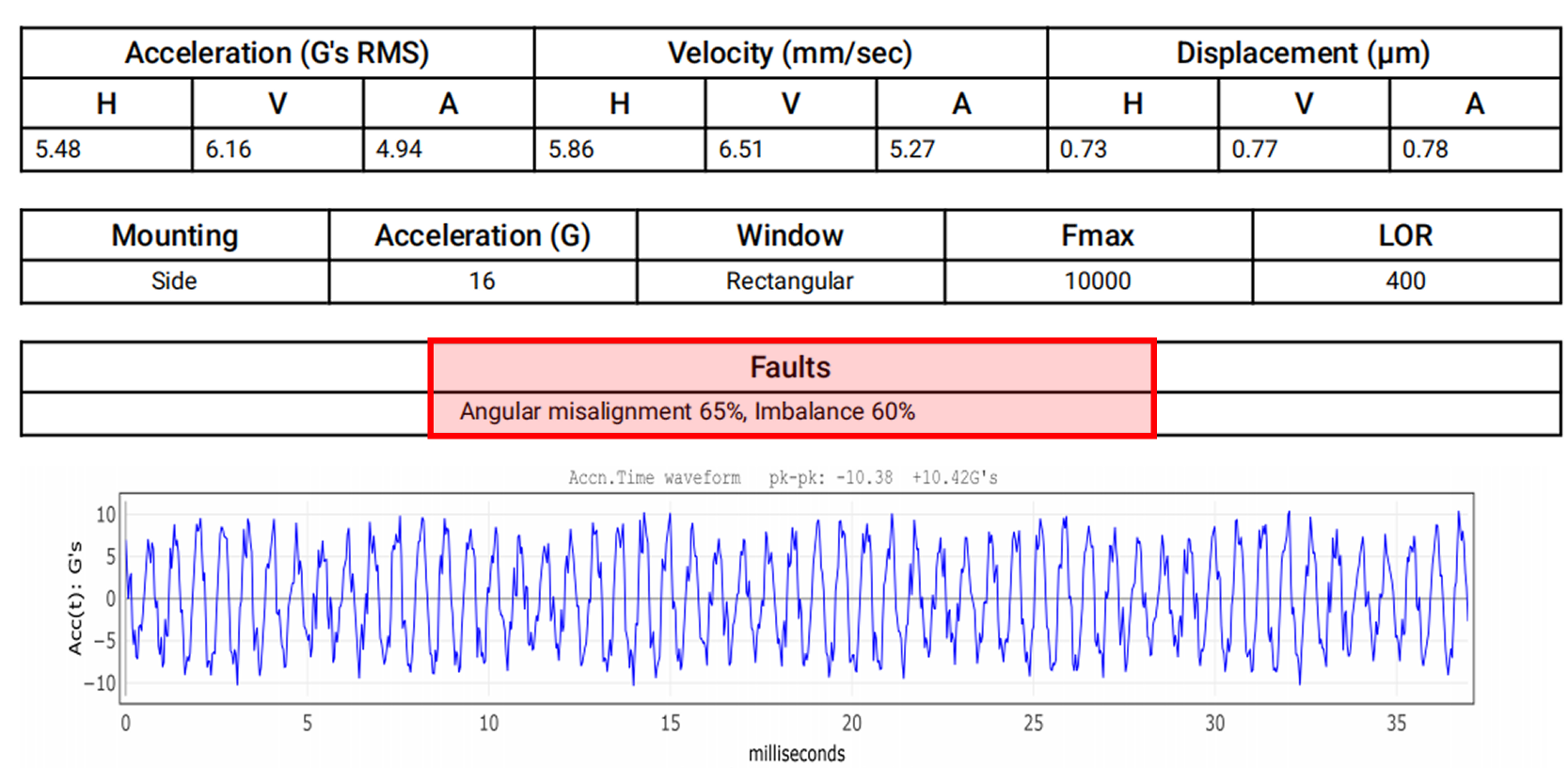

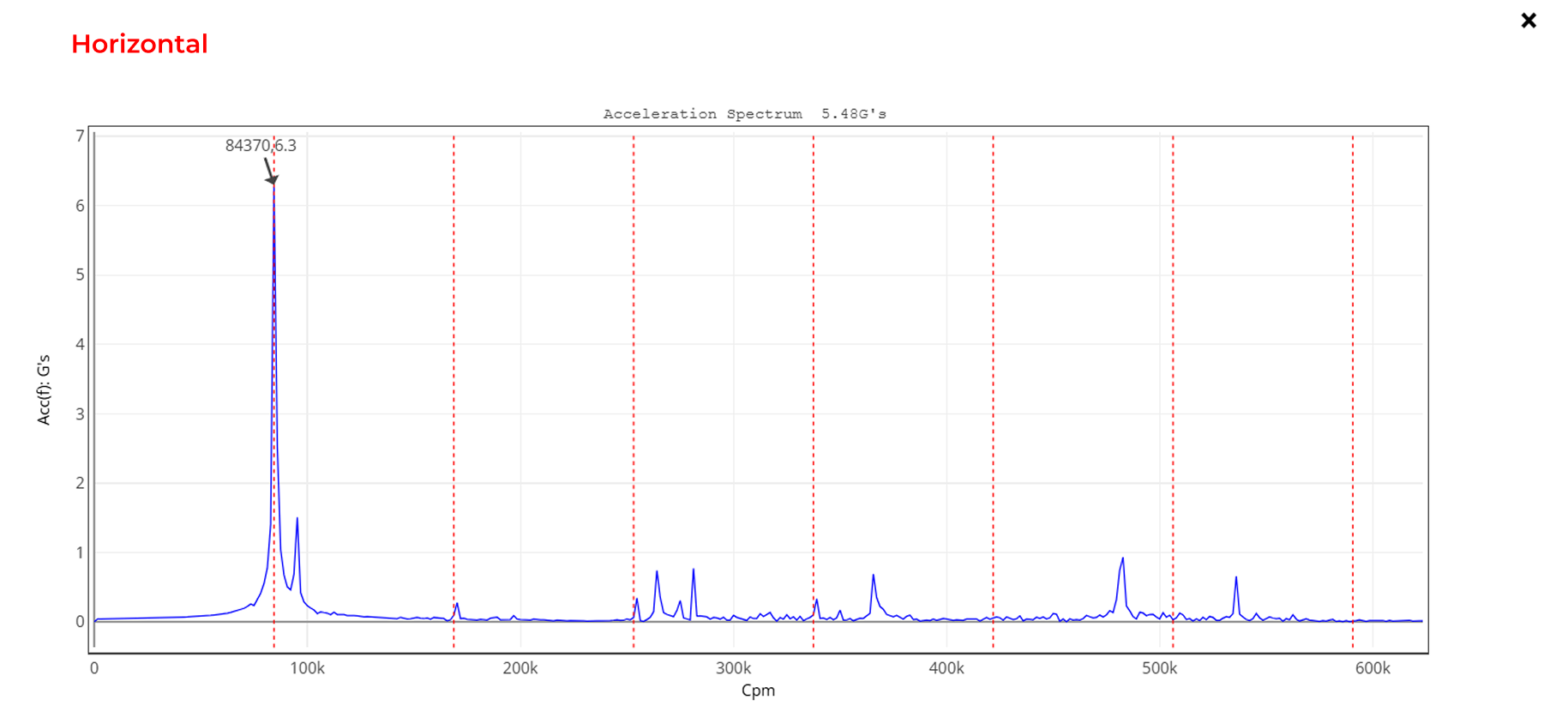

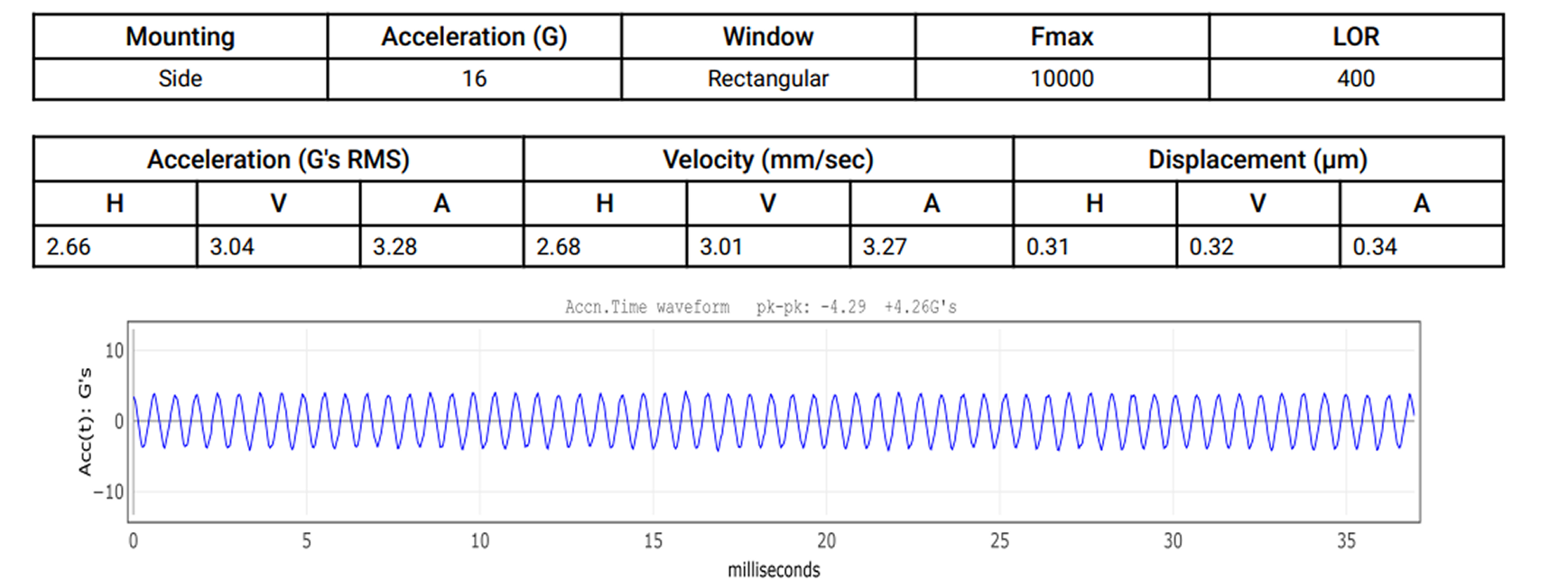

The Unit 2 bore spindle recorded a significant rise in acceleration, peaking at 6g— well beyond the critical threshold of 4.5g.

- FFT and Time Waveform (TWF) analysis revealed distorted sinusoidal signals with sharp spikes and harmonic distortion.

- The AI diagnostic system automatically detected that there was a fault, flagged as angular misalignment and imbalance.

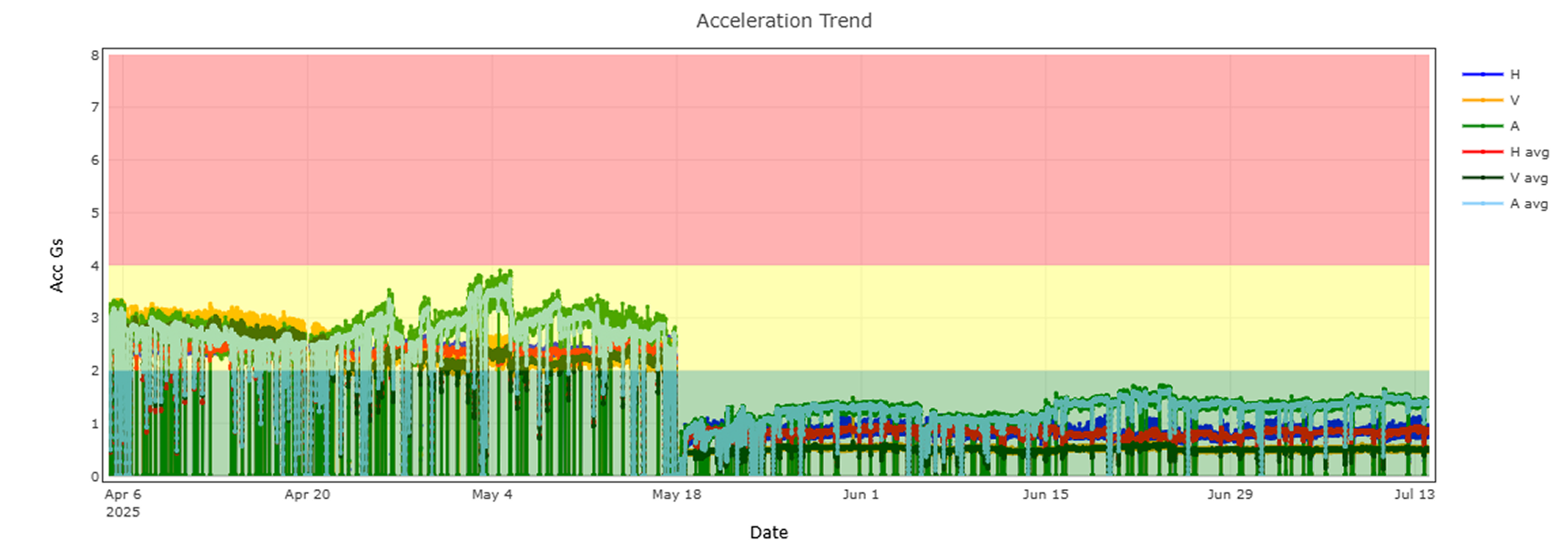

Figure 2: Acceleration trend plot showing rise from Mar 11

Figure 3: RMS values, time waveform during faulty condition, with AI-powered fault detection

Figure 4: Horizontal axis acceleration in CPM

The issue was traced to a misaligned grinding wheel. Proactive replacement was carried out before bearing damage occurred.

(Estimated cost avoided: ₹8–10 lakhs (cost of bearing, disassembly, rebalancing, downtime)

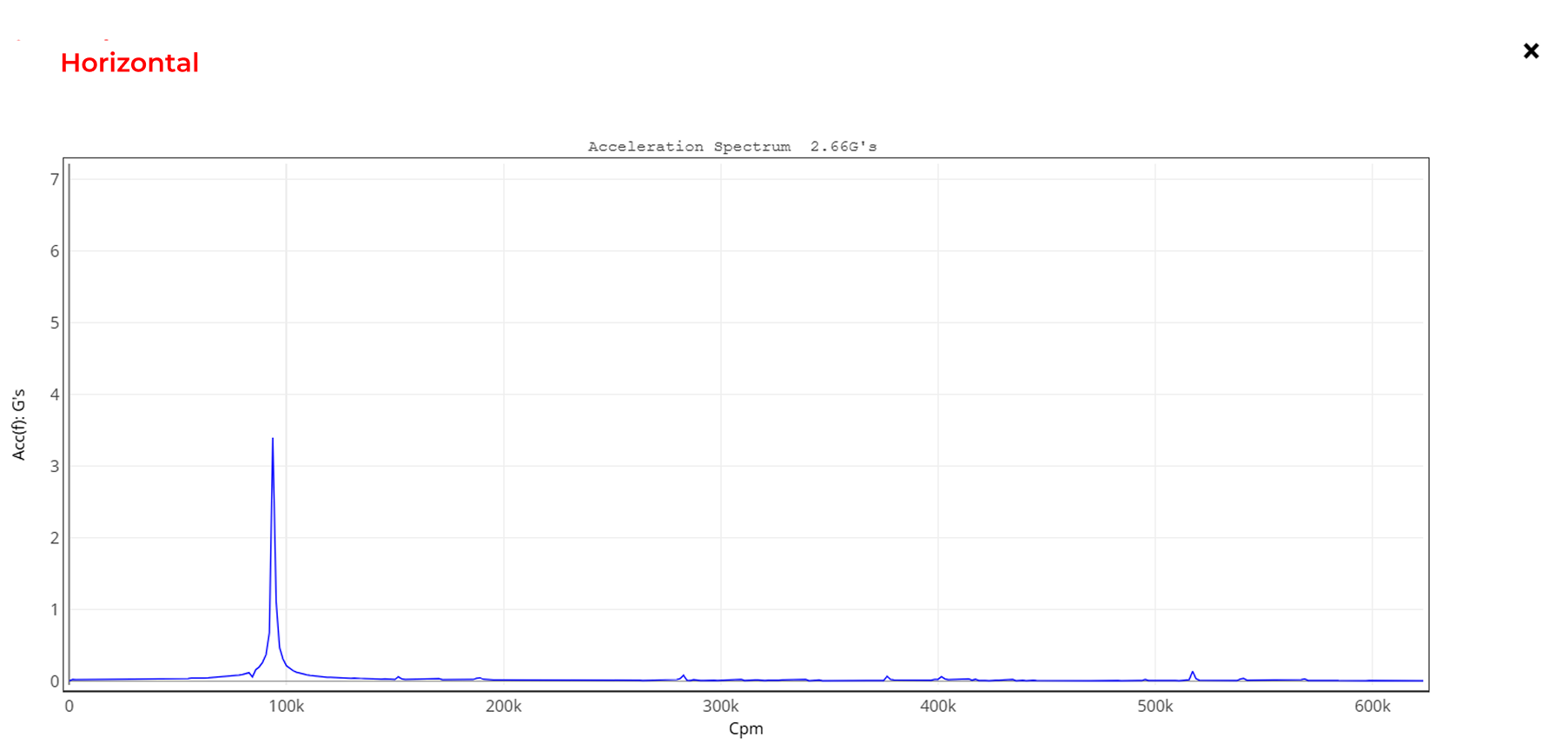

- Vibration signals returned to a stable sinusoidal pattern.

- Acceleration remained within marginal-to-normal range (~3g), with FFT showing reduced peaks.

Figure 5: Acceleration post-overhaul time waveform and spectrum

On May 18, the Unit 2 seat spindle (part of the tandem spindle set) was replaced after its acceleration values reached the critical threshold. Following this replacement, the Unit 2 bore spindle—which had previously remained in the marginal zone—returned to normal vibration levels, indicating that the seat spindle’s condition may have been affecting the overall system stability.

Results: From Reactive to Predictive

Implementing ARGUS delivered significant business value:

- 80% reduction in unplanned downtime

- Spindle issue resolved in 3 days instead of the typical 7+ days

- ₹8–10 lakhs in failure costs avoided by proactively replacing a defective grinding wheel before it led to bearing damage

- No quality deviation or part rejection — machining precision was maintained throughout

- Rugged ARGUS sensors performed reliably despite high-speed coolant spray and harsh factory conditions

As of May 2025, the Unit 2 bore spindle continues to operate under 2g acceleration, confirming long-term stability and the success of predictive diagnostics.

Why This Matters

This case study shows how AI-powered real-time vibration monitoring can prevent failures before they escalate — transforming maintenance from a reactive cost center into a proactive value driver.

When standard thresholds and manual checks fall short, systems like ARGUS offer actionable insights that are measurable, repeatable, and scalable across high-speed, high-precision operations.

Want to enable predictive maintenance in your operations?

Contact SANDS to learn how ARGUS can protect your critical rotating equipment and optimize uptime.